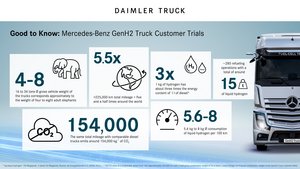

Five and a Half Times Around the World: Daimler Truck Fuel Cell Trucks Successfully Complete More Than 225,000 Kilometers

- Five Mercedes-Benz GenH2 Trucks have successfully completed more than 225,000 kilometers in initial customer trials with Air Products, Amazon, Holcim, INEOS Inovyn, and Wiedmann & Winz

- In principle just like a diesel truck, without local CO2 emissions: fast refueling and long ranges enable practical integration into regular logistic operations

- Average hydrogen consumption of fuel cell trucks ranged between 5.6 kg/100 km and 8 kg/100 km, depending on use case with an average gross vehicle weight between 16 tons and 34 tons

- 285 refuelings with a total of around 15 tons of liquid hydrogen (sLH2 standard) in Woerth am Rhein, Southern Germany, and Duisburg, Western Germany

- Michael Scheib, Head of Entire Vehicle Development at Mercedes-Benz Trucks: “The initial customer trials are extremely valuable for the further development of our fuel cell trucks. By deploying the GenH2 Trucks in real-world logistics operations, we have been able to demonstrate their performance, reliability and efficiency across various transport applications and gain important insights. This enables us to refine the technology and vehicles according to the specific needs of our customers all the way to series production. Furthermore, the intensive use of the liquid hydrogen fueling stations during the trials enables further optimization of the refueling process. All these practical experiences also help us to optimally prepare our sales and service for the deployment of hydrogen trucks for our customers.”

Leinfelden-Echterdingen, Germany – Daimler Truck looks back on a successful year of initial customer trials for its Mercedes-Benz GenH2 Truck. In July 2024, the company started the trials with the deployment of five Mercedes-Benz GenH2 Trucks together with Air Products, Amazon, Holcim, INEOS Inovyn and Wiedmann & Winz in regular logistics operations. The aim was to test the reliability and efficiency of the vehicles under real-world conditions and to give these customers the early opportunity to gain first-hand experience in transporting goods with fuel cell trucks. In total, the five prototypes have now covered more than 225,000 kilometers in customer operations. This distance corresponds to about five trips around the earth along the equator. For the same total distance, a comparable diesel truck with a gross combination weight of 25.6 tonnes would have had to refuel around 58,000 litres of diesel, emitting around 154 tonnes of CO2*.

During the almost year-long deployment, the prototypes of the Mercedes-Benz GenH2 Truck impressed with the high efficiency of its fuel cell, which is developed and manufactured by cellcentric, a joint venture of Daimler Truck and Volvo Group. Over the total mileage, the average hydrogen consumption lay between 5.6 kg/100 km and 8 kg/100 km depending on the application, with an average gross combination weight between 16 tons and 34 tons.

Michael Scheib, Head of Entire Vehicle Development at Mercedes-Benz Trucks: “The initial customer trials are extremely valuable for the further development of our fuel cell trucks. By deploying the GenH2 Trucks in real-world logistics operations, we have been able to demonstrate their performance, reliability and efficiency across various transport applications and gain important insights. This enables us to refine the technology and vehicles according to the specific needs of our customers all the way to series production. Furthermore, the intensive use of the liquid hydrogen fueling stations during the trials enables further optimization of the refueling process. All these practical experiences also help us to optimally prepare our sales and service for the deployment of hydrogen trucks for our customers.”

Customer Deployment Confirms Practicality

The five GenH2 Trucks were deployed by customers on specific routes within Germany during the trial period and took on various transport tasks. For example, Amazon’s transportation partner used the Mercedes-Benz GenH2 Truck within Amazon’s logistics network on a dedicated route between the Fulfillment Center in Frankenthal (Rhineland-Palatinate) and the Delivery Station in Sindelfingen (Baden-Wuerttemberg). Air Products used the Mercedes-Benz GenH2 Truck for the transportation of bottled gases from its bottle filling plant in Hattingen on the Ruhr River and supplied gas centers and customers from there. Wiedmann & Winz deployed the hydrogen truck in a so-called 'combined transport' application, whereby trucks take over a section of a transport task in combination with other transport modes. Thereby, the Mercedes-Benz GenH2 Truck transported sea containers to industrial and commercial customers for the international logistics service provider DP World. Holcim deployed the fuel cell truck for its construction material logistics to transport cement deliveries from its plants in the Ruhr area to its customers in Western Germany and the Netherlands. VERVAEKE - the logistics partner of INEOS Inovyn - used the GenH2 Truck for PVC and vinyl transport. During the initial customer trial phase, the prototypes remained under the direct supervision and responsibility of the manufacturer.

Direct customer feedback regarding the trials confirms that the vehicles integrated reliably and smoothly into daily logistics operations. In particular, customers emphasized the practicality similar to that of today’s diesel trucks, among other things due to the long range of 1,000 kilometers and more, as well as short refueling times of 10 to 15 minutes. This makes the GenH2 Truck especially suitable for long-distance haulage, flexible routes and unplanned deployments. Drivers also praised the dynamic power delivery, smooth and comfortable ride, and low noise levels – all advantages that the Mercedes-Benz GenH2 Truck can leverage as an electrically powered vehicle that uses hydrogen as an energy source and with a fuel cell output of 300 kW and a 70-kWh battery for situational power peaks. Overall, customer feedback underlines the reliable operation and practical usage of hydrogen-powered fuel cell trucks.

Thomas Hollad, Transport and Asset Manager Northern Continent, Air Products: “The vehicle has operated reliably throughout the trial, and the Daimler Truck team’s responsiveness and technical support have been valuable in resolving any minor issues quickly and professionally. We’re pleased to be contributing to these trials — both as a customer and by supplying hydrogen at our refueling station in Duisburg”

Fabian Duex, Director EU Surface Transportation Operations, Amazon Transportation Services: “The GenH2 Truck has performed well in our transportation partner’s operations, demonstrating solid reliability and fuel efficiency. During the trial, it consistently achieved ranges of over 1,000 kilometers on a single tank, and the truck operated smoothly in a five-day-a-week schedule. Based on our partner’s experience with the pre-series vehicles, the GenH2 Truck shows promising maturity.”

Roger Haschka, Global Category Manager Trucks & Trailers, Holcim Technology Ltd.: “The Mercedes-Benz GenH2 Truck demonstrates that hydrogen propulsion is a viable technology for the future. Payload and range meet our requirements.

For the sustainable decarbonization of our Scope 3 emissions – in addition to the use of battery-electric trucks – the key challenge for the industry is to create an economical, TCO-based business case that allows the vehicle to be operated without cost disadvantages.”

Fritz Ehlers, Gerdes + Landwehr, Partner to the Holcim Group: “We at the Gerdes and Landwehr group are absolutely delighted to be able to accompany this project together with Holcim Technology Ltd. and to gain valuable insights into future technologies at an early stage. The driving comfort, especially in terms of noise emissions, as well as the performance that the vehicle delivers on the road, already delights our drivers. Excitement for the series version is already building today.”

Frédéric Derumeaux, CEO VERVAEKE: “From the outset, we received excellent support from the Mercedes-Benz GenH2 Truck engineering and customer service teams. Any initial difficulties were dealt with very quickly and competently. Together with our customer INEOS Inovyn, we were able to achieve high operational performance, which was only possible thanks to the flexibility and coordination of all those involved. The drivers who used the Mercedes-Benz GenH2 Truck grew to love it in operational use and appreciate both its powerful performance and comfort.”

Dr. Micha Lege, Managing Director, Wiedmann & Winz: “The Mercedes-Benz GenH2 Truck is on a par with the diesel Actros in many ways – that makes it so valuable for us. Due to the high range and the short refueling times, we can deploy the GenH2 Truck like a diesel truck. We cannot afford to rely on just one technology. In order for the drive system revolution to work, we need a technology mix of battery-electric and hydrogen trucks. With the fuel cell from cellcentric, we use state-of-the-art technology made in Germany.”

Jens Langer, Managing Director DP World Intermodal: “The Mercedes-Benz GenH2 Truck proves that hydrogen drive and everyday practicality go hand in hand. With strong performance, high driving comfort and a seamless interplay between engineering, driving operations and service, it sets new standards for future-oriented, climate-friendly logistics.”

A major challenge on the way to the series production of fuel cell trucks remains the continued lack of a comprehensive network of hydrogen refueling stations, particularly for liquid hydrogen. By 2030, there is a requirement to expand the network across Europe to a total of 2,000 hydrogen refueling stations in order to enable the deployment fuel cell trucks in large numbers in practice.

Customers also noted that a positive TCO (Total Cost of Ownership) view, i.e. the total operating costs of fuel cell trucks compared to diesel trucks, is not possible at the moment, on the one hand due to the current high price for hydrogen, but also due to high vehicle insurance costs.

Refueling with Liquid Hydrogen

The vehicles were refueled by the drivers at liquid hydrogen (sLH2) filling stations in Woerth am Rhein (Rhineland-Palatinate) and the Duisburg area (North Rhine-Westphalia). In total, 285 refuelings were carried out as part of the customer trials with a total of around 15 tons of liquid hydrogen. When developing hydrogen-based drive technologies, Daimler Truck prefers liquid hydrogen. In this aggregate state the energy carrier has a significantly higher energy density. As a result, more hydrogen can be added to the two tanks, each with a capacity of 40 kg, which significantly increases the range and enables comparable performance of the vehicle with that of a conventional diesel truck. Liquid hydrogen is also much easier to transport, and liquid hydrogen tanks offer advantages in terms of cost and weight compared to compressed gaseous hydrogen tanks. Thus, the use of liquid hydrogen enables a higher payload -- an important criterion in flexible and demanding long-distance haulage.

Comprehensive Service Support for Mercedes-Benz GenH2 Trucks in Germany

During the trials, Daimler Truck provided close support for vehicles and customers. Servicing hydrogen trucks did not only require new technical expertise but also demanded adapted processes and workflows in After-Sales. During the entire trial period, the five fuel cell trucks were supported by Key Account Managers within the Mercedes-Benz Trucks sales organization. This ensured that each customer had a dedicated single point of contact providing continuous full-service support, including technical assistance. The Key Account team was available around the clock for technical questions and able to refer customers to Mercedes-Benz Trucks branches with specially trained staff if needed. For the customer trials, the branches in Haan (North Rhine-Westphalia) and Stuttgart-Feuerbach (Baden-Württemberg) were specifically trained and certified for the GenH2 Truck. Highly qualified service personnel took care of regular checks, routine maintenance, and, where necessary, repairs.

A project-oriented, efficient, and direct collaboration between the development team and after-sales experts ensured optimal information exchange, ultimately providing the best possible customer support for vehicle operations. Customers recognized the close coordination among drivers, engineering, and customer service as a key success factor during these initial customer trials.

Based on these experiences, further after-sales locations are being prepared for handling fuel cell trucks, to optimally support the planned 100 small-series vehicles of the next generation of the Mercedes-Benz GenH2 Truck.

Outlook: Second Trial Phase and Further Development of the Mercedes-Benz GenH2 Truck

As planned, Daimler Truck will follow up with a second round of trials with the same Mercedes-Benz GenH2 Trucks and five further customers starting in the fourth quarter of 2025. The aim is to gather further experience with another set of use cases in real-world operations and optimally prepare the fuel cell trucks for series production on the basis of customer requirements.

Daimler Truck has already started the development phase for the next generation of fuel cell trucks in parallel. A total of 100 next generation fuel cell trucks are planned to be assembled at the Mercedes-Benz plant in Woerth as part of small series production and deployed at various customers from the end of 2026 onwards.

When it comes to decarbonizing transportation, Daimler Truck pursues a dual-track strategy with battery-electric and hydrogen-powered vehicles. However, progress in building out hydrogen refueling stations has been much slower than expected. As a result, customers will not be able to operate hydrogen trucks in large numbers in the next couple of years. Therefore, the large-scale industrialisation of fuel cells and the planned series production of hydrogen-powered trucks with a focus on Europe is planned for the early 2030s.

*VECTO value of a comparable diesel truck over approximately 225,000 km with a total gross combination weight of 25.6 tons (-> total mileage and Ø gross combination weight of the GenH2 Truck customer fleet).

-

Anja Weinert

Spokesperson Corporate Communications Daimler Truck North America